President Chain Store Corporation reduces loss of resources in four major aspects, including environmental and energy management, packaging material, waste disposal including food loss and waste, and water management.We aim at effectively using resources and reducing waste through the 3R principle, namely reduce, reuse and recycle.

Environmental and Energy Management

- Policy and Commitment

To realize the vision of green operations, President Chain Store Corporation has formulated “Environmental Policy”, “Energy Policy”, and “GHG Policy” as the guiding principles for the Group’s actions on environmental issues. Based on the policies, President Chain Store Corporation realize sustainability in our operations and business model, making green consumption a part of daily life.

- Environmental Policy

President Chain Store Corporation is dedicated to becoming the best retailer, providing the most convenient lifestyle services and fulfilling our responsibilities as a corporate citizen. To this end, four task forces of “Plastic Reduction,” “Carbon Reduction,” “Food Waste Reduction” and “Sustainable Procurement” under the Environmental Group of the ESG Committee have been selected to take charge of ESG policies, systems or management regarding various environmental aspects as well as proposing and formulating concrete action plans. Our commitments are as follows:

- Comply with environmental protection laws and regulations and prohibit any behavior that may harm the environment.

- Continuously improve our environmental protection performance, as well as optimizing our surrounding environment.

- Cherish the use of resources and increase recycling and reuse, sticking to the principle of “making the most of resources.”

- With consideration to the environmental impact of our products and services in each phase of the life cycle from R&D, design, manufacturing, packaging to delivery, we will reduce resource consumption and increase the efficiency of resource use.

- Build up an eco-friendly value chain step-by-step, take environmental aspects into the suppliers screening, new projects developing and decisions making of merge and acquisition.

- Care for community development and manage sustainable relationships with local communities.

- Promote environmental education and training, share environmental protection concepts with stakeholders like employees and customers in order to protect the environment together.

- Set short- and medium-term environmental management goals to actively reduce the negative impact on the environment from the production process to the value chain of distribution and logistics.

- Promise to achieve the net-zero emissions target for Taiwan’s store operations by 2050 in response to the Paris Agreement’s global strategy of limiting global warming to within 1.5°C.

- Commit to reducing 30% of plastic consumption for President Chain Store Corporation’s private-label packaging/materials by 2030 compared to 2019, in line with the Global Plastics Treaty.

Note:Please refer to the “Policies and Documents” page for the Environmental Policy.

- Energy Policy

As we strive to meet customer needs, we have made energy conservation and carbon reduction actions a core value of our business strategy. We use our stores as a base for energy conservation and carbon reduction by maximizing our advantage as a retail channel. We also exert our influence through the benefits of energy conservation.

Our commitments:

- Complying with the government’s energy laws and regulations and continuing to make energy improvements.

- Expanding stores with energy saving designs and developing and selling energy-efficient products.

- Optimizing our energy use to achieve sustainable corporate development.

| Energy Management Programs |

Management Actions in 2023 |

| Energy audits to identify opportunities for improving energy performance |

President Chain Store Corporation tracks electricity consumption of retail stores quarterly and sets annual Energy Use Intensity (EUI) targets for each store. This approach allows us to conduct energy audits on stores that have energy-saving potential or abnormal electricity consumption,thereby further improving energy performance.

|

| Quantified targets to address energy savings |

Our target to address energy saving is to achieve a 0.5% reduction in Energy Use Intensity (EUI) compared to the previous year, and we successfully achieved a 0.81% decrease in 2023, meeting the annual target.

|

| Actions to reduce the amount of energy use |

President Chain Store Corporation has formulated basic requirements for equipment and store environment management for new and existing stores to improve energy efficiency by incorporating 7 energy-saving designs :

- Heat insulation

- Energy saving signboards

- Lamp reduction

- Reduction of window area

- Frequency conversion system

- LED lamps installation

- Indoor lighting management

Additionally, the energy-saving windbreak room was introduced on some stores. Existing stores actively evaluate the feasibility of introducing various energy-saving measures and gradually replace high-efficiency equipment.

|

| Evaluation of progress in reducing energy consumption |

In 2023, President Chain Store Corporation's retail stores successfully saved 116,738,105 kWh of electricity through energy-saving projects, which is equivalent to reducing indirect emissions of 57,669 metric tonnes of CO2e.

|

| Use of clean or green energy |

President Chain Store Corporation introduced the photovoltaic system to 7-ELEVEN Yawan store in 2022, which started generating electricity in 2023. The Yawan store generated and used 3,000 kilowatt-hours of renewable energy at the Yawan store as part of its transition to low-carbon economy.

|

| Investments in innovation or R&D to decrease energy consumption |

In 2023, President Chain Store Corporation invested NT$ 322,722,787 in 7 energy-saving designs for its retail stores to decrease energy consumption.

|

| Energy efficiency training provided to employees to raise awareness of energy consumption reduction |

In order to raise awareness of energy consumption reduction,"In-store energy-saving and carbon reduction measures" training was provided for all store employees and franchisees, with a total training time of 785 person-hours in 2023.

|

- Net Zero Commitment and Emissions Reduction Policy

As a member of the global village, President Chain Store Corporation lays great emphasis on the use of energy and resources, as well as the environmental impact. To fulfill our corporate responsibilities, we will control and manage the current status of greenhouse gas emissions and promote energy-saving and carbon-reduction plans based on the result of the inventory. President Chain Store Corporation has committed to achieving net-zero for Scope 1 and 2 greenhouse gases within its operations by 2050.

- External Assurance

Packaging Material Management

In 2022, a total of 175 countries around the world signed the Global Plastics Treaty to formulate specific and mandatory regulations for solving the problems of plastic waste in various countries from production, consumption to disposal, as well as gradually limiting and reducing the use of plastics. To respond to the global trend in plastic reduction, stakeholders’ concerns about plastic pollution and strengthen sustainable operations,President Chain Store Corporation hopes to strike a balance between convenience and environmental impact by committing to reducing plastic pollution in its own operations. To this end, President Chain Store Corporation has planned ahead of the schedule for international conventions. It set up a Plastic Reduction Task Force in 2020 to formulate a comprehensive management policy for private-label product packaging materials to achieve a business model striving for plastic reduction and environmental protection from top to bottom. Starting from the private-label brand, we actively carry out plastic reduction management actions, integrate various operations strategies such as products, services, logistics and e-commerce in order to achieve the vision of completely phasing out single-use plastics in our operations by 2050.

- Private-Lable Products Packaging Materials Policies and Commitments

- The procurement of eco friendly, certified packaging materials and lightweight packaging design should be prioritized in consideration of environmental and ecology protection, while achieving sustainable operations. A target for packaging reduction for Private-Lable products has also been set.

-

Reduce the amount of single-use plastic at the source:

- The stores no longer offer customers straws. Without providing plastic net bags for free, plastic consumption reduced by 22.62 metric tonnes, resulting in a 94.61% reduction compared to 2022.

- Ice makers were introduced to reduce the amount of plastic packaging used for ice cubes. A total of 62.8 million plastic bags were reduced in 2023, the equivalent of 125.6 metric tonnes of plastic reduction.

-

President Chain Store Corporation worked with President Packaging Ind. Corp., an affiliated company, to establish and develop circular cup renting services to transit from manufacturing single-use containers to developing reusable containers.

- Introduced the “OPEN iECO Recycled Cups Renting Service” as part of the recycling mechanism in compliance with regulations. 1,042 stores adopted the “OPEN iECO Recycled Cups Renting service” in 2023, exceeding our target of 1,000 stores. 18.90% of consumers brought their own cups, exceeding the annual target of 15.00%.

- We also encourage the consumers to use reusable packaging materials (or containers). A reward is also given for consumers who use their own reusable cups for fresh brewed beverages. President Chain Store Corporation responded to the regulation in advance, bringing own reusable cup according to the regulations of the Ministry of Environment will entitle the customers to a discount of NT$5. Moreover, on the first of each month, bringing own reusable cup for “CITY” brand fresh brewed beverages will entitle them to an NT$7 discount.

-

Packaging materials for cup sleeves and cup holders are made of recycled materials, with the cup sleeves consisting of 65% recycled paper and the cup holders consisting of 100% recycled paper.

- FSC certified paper cups were introduced and used in retail stores in 2023.

- President Chain Store Corporation has set up Plastic Reduction Task Force as an internal cross functional team to consolidate the Company’s efforts in plastic reduction. By combining the power of internal employees and external suppliers, The Plastic Reduction Task Force promotes packaging plastic reduction strategies, targets, and action plans, while holding regular meetings to ensure the progress of each actions. The task force took about NT$2.5 million each year in manpower and testing resources, such as task force operations, R&D, testing costs in manpower and raw materials.The Plastic Reduction Task Force also stays on top of information on external competitiveness and the industry with the assistance of consulting company.

- Plastic Reduction Target

| Target Year |

Target |

| 2023 |

- Proportion of other single-use plastic being less than 20%.

- Expected to convert 128.77 metric tonnes of paper into FSC certified paper by 2024. (The target was achieved in 2023 with FSC certified paper packaging weighing 3,786.75 metric tonnes.)

|

| 2028 |

- Proportion of other single-use plastic being less than 10%.

- Eliminate disposable shopping bags and plastic straws (Note).

|

| 2050 |

- Completely eliminate other single-use plastics (0%).

|

Note: In line with the Ministry of Environment’s policy, President Chain Store Corporation no longer offers plastic bags, straws and net bags for takeaway. The targets above are imposed for occasions when consumers ask for straws, purchase plastic bags and net bags. In the future, plastic bags and straws for takeaway will no longer be provided or will be replaced by non-plastic ones.

- Plastic Reduction Management Actions

President Chain Store Corporation has engaged in three aspects to reduce plastic, including “reduction at the source,” “innovative packaging” and “encouraging customers to bring their own containers” since 2019. The Plastic Reduction Task Force was set up in 2020 to integrate strategies related to plastic reduction. We have started with the reduction of single-use plastics in private-label products and services, redesigned product packaging to reduce plastic consumption, introduced certified paper materials and recycled plastics, as well as reducing single-use containers by offering discounts for customers. In addition, President Chain Store Corporation integrated Group resources to set up the “OPEN iECO Recycled Cups Renting Service” in 2022. By the end of 2023, a total of 1,042 stores have been incorporated with the hope of providing convenient services while working towards environmental protection.

Phasing out single-use plastic in product packaging and store services

【Description】

- Adopt lightweight, low plastic design for packaging

- Reduce weight and change materials for store service consumables and disposable cutlery

【Case】

- Joint work with Uni‑President Enterprises Corporation to introduced "label free" bottled water, reducing plastic consumption by 0.46 tonnes compared to regular bottled water

- Weight reduction of plastic for each fork by 28%, and for each spoon by 15%

- Ice makers introduced in stores to reduce ice cube packaging. In 2023, the ice makers were introduced to a total of 2,457 stores, reducing a total of 125.6 metric tonnes of single-use plastic

- The users pay approach for coffee and fresh food net bags with a significant impact on reducing the number of net bags consumed by 94.61%

- Film sealing machines were introduced in stores to reduce the consumption of single-use cup lids. the film is expected to reduce plastic consumption by 53.62%

- Paper packaging for boxed meal reducing approximately 894 metric tonnes of plastic.

- 592,000 reusable shopping bags were sold

Increasing the use of reusable packaging- Provide “OPEN iECO Recycled Cups Renting Service” and Bring-Your-Own-Cups discount.

【Description】

- Installation of“OPEN iECO Recycled Cup Return Machine”to reduce negative impact of single-use cup

- Offering discounts for bringing your own cup that exceed regulatory requirements

【Case】

- 1,042 stores offering reusable cups for rent in 2023

- 18.90% of consumers bringing their own cups in 2023

- To ensure that reusable cups are actually reusable, a pre paid fee is charged with barcode in the"OPEN POINT" app. The pre paid fee will be automatically deducted if the cup is not returned in time

Increase recyclable packaging

【Description】

【Case】

- PLA tea egg boxes were gradually replaced by recyclable PET material

- Coffee lids material changed to PET

- Reheatable fresh food containers are made of PP

Upgraded recycling mechanism

【Description】

- “Intelligent automatic recycling machines” and recycling areas launched in stores to increase the efficiency of recycling and ensure that recyclable materials can be recycled

【Case】

- Intelligent automatic recycling machines:The scale was further expanded in 2023 with 140 stores adopting the machine, recycling a total of 7.912 million PET bottles and 2.748 million batteries. It is estimated that a total of 262 machines will be installed by the end of 2024

Allocation of R&D resources to sustainable packaging solutions

【Description】

- Plastic Reduction Task Force promotes packaging plastic reduction strategies, targets, and action plans, while holding regular meetings to ensure the progress of each actions. The task force took about NT$2.5 million each year in manpower and testing resources, such as task force operations, R&D, testing costs in manpower and raw materials

Adoption of plastics with recycled content

【Description】

- Replace the use of virgin plastic with recycled plastic in packaging materials and garbage bags

【Case】

- 100% of garbage bags used in stores made of recycled materials

- Cup holders and sleeves made by recycled paper

- Recycled PET (rPET) made from PET bottles has been adopted in two fresh salad packaging containers. rPET will also be used in the packaging of two types of fresh sushi rolls

- 2020-2023 Statistics of Plastic Packaging Materials

- 2020-2023 Statistics of Non-Plastic Packaging Materials

Note:

- The scope of statistics extends to President Chain Store Corporation’s private-label product packaging, packaging of retail store products and services and for delivery purposes. The statistics of plastic packaging materials cover 100% of private-label products; the statistics of non-plastic packaging materials cover 100% of private-label products.

- Metal packaging materials for iseLect beer were added in 2023.

- FSC-certified packaging and packaging material items: refrigerated beverages, store supplied disposable chopsticks and coffee stirrer.

Waste, Food Loss and Waste Management

- Policies and Commitments

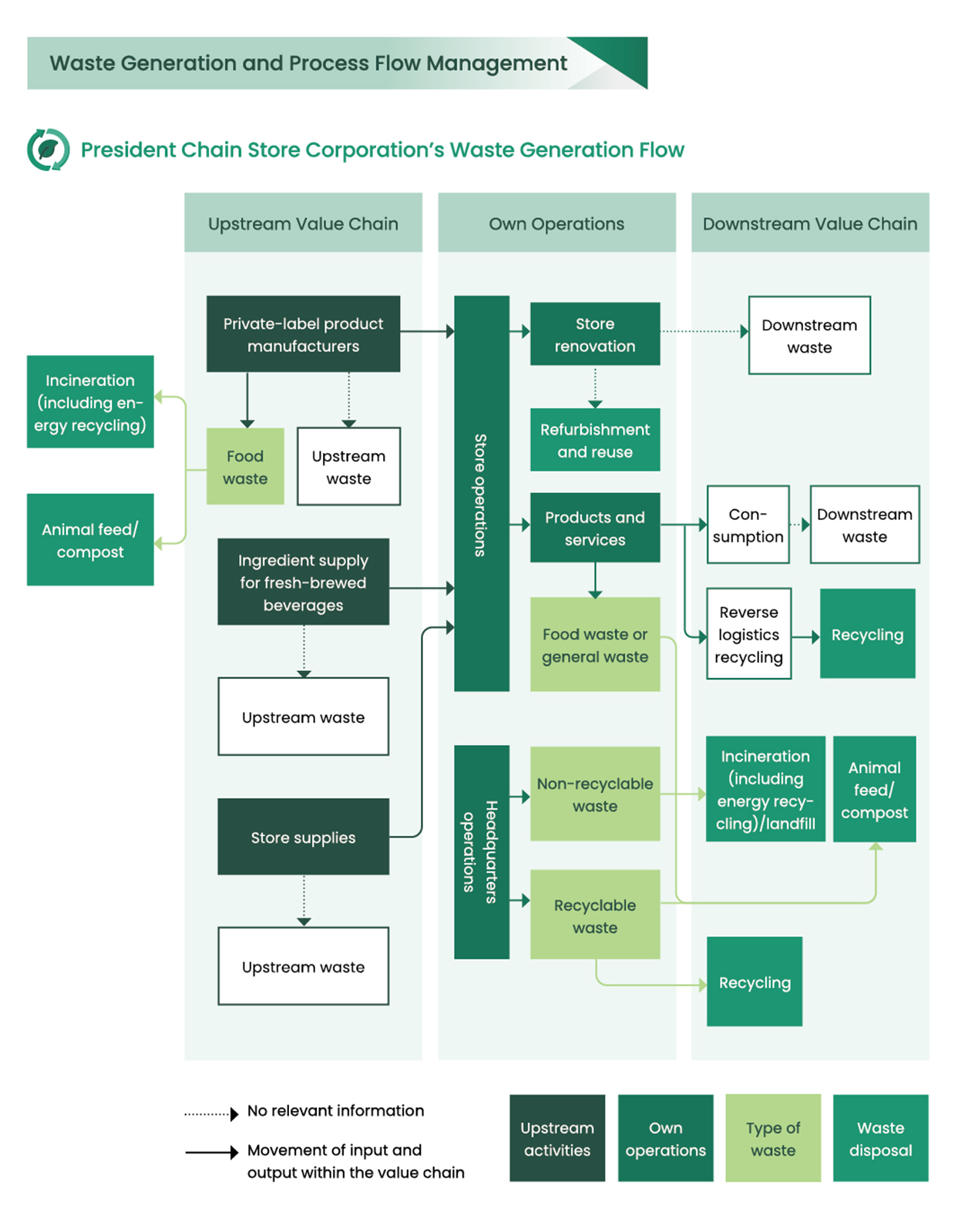

Due to the service of convenience stores, waste generated mainly includes general waste and food waste. Waste management has gradually become an unavoidable and significant issue for President Chain Store Corporation. To effectively manage waste generated from operations,we have established "President Chain Store Corporation Waste Management Policy", developing medium to long term targets, strategies,and management actions:

| Waste Management Programs |

Management Actions in 2023 |

| Waste audits to identify opportunities for improving waste performance |

President Chain Store Corporation conducts waste data statistics and audits each year to understand the main sources of waste generation that are closely related to store operations, including food waste and general domestic waste generated by store services. In addition to waste from our operations, we also attach great importance to the waste management of fresh food manufacturers in the upstream of the value chain. We regularly count the food waste generated by the manufacturers and track the food waste disposal to identify opportunities for improving waste performance. Based on waste statistics, we have taken the specificities of the food retail industry into consideration to focus on the management of food waste and packaging materials for waste reduction.

|

| Action plans to reduce waste generation |

- Convenient Recycling Platform: Recycling PET, electronic waste, including batteries, laptops, optical discs, mobile phones and chargers.

- Store Equipment Reuse: The recycling system works on existing equipment from renovated and shut down stores, such as air conditioners, refrigerators, oden cooking machines, microwave ovens and so on. It is returned and put to use after inspecting, cleaning and repairing.

- iLove Food Program: A 35% discount is given 8 hours prior to expiration on over 100 products to reduce food loss and waste.

For more actions regarding waste reduction, please refer to Sustainability Focus - Circular Economy

|

| Quantified targets to minimize waste |

- Food loss and waste: Commit to halving food waste discarded by 2030 as the target (with 2019 as the base year for the amount of food waste from the stores and manufacturers)

- Waste: Reduce the volume of waste removal from a single store by 45% in 2028, reducing by 38% in 2024; reducing by 35% in 2023(with 2019 as base year).

|

| Investment in innovation or R&D to minimize waste |

President Chain Store Corporation promotes packaging plastic reduction strategies, targets, and action plans, We took about NT$2.5 million each year in manpower and testing resources. We continue to introduce circular economy initiatives to achieve waste reduction, including iLove Food Program implementation, developing “OPEN iECO Recycled Cup Return Machine” for recyclable packaging, installation of “Intelligent automatic recycling machines”, and establishment of customer incentives for recycling. Please refer to the "President Chain Store Corporation Climate-related Disclosures Report" for future related investment and R&D to minimize waste.

|

| Waste reduction training provided to employees |

- All employees and store franchisees took part in the “Plastic Reduction Digital Course” for a total of 677 people hours in 2023.

- “Recycling and Coffee Ground Reuse” was communicated to store employees and store franchisees for a total of 167 people hours.

- The “Plastic Restriction Policy on Straws” was provided to all store employees for a total of 45 people hours in 2023.

|

| Integration of recycling programs to reduce the waste sent to landfill |

President Chain Store Corporation provides OPEN iECO recycled cups so that cups and lids for freshly-prepared drinks can be recycled and reused to reduce the consumption of single-use paper cups. We recycle coffee ground and expiring fresh food from the stores through the Sustainable Farm project, reducing the amount of food waste in the landfill.

|

| Waste diversion from landfill is certified by an independent accredited body |

The total volume of waste generated by President Chain Store Corporation in 2023 was 64,294.39 metric tonnes, of which 2,534.36 metric tonnes went to landfills (Note 1). The remaining volume was diverted to animal feed/compost, incineration (including energy recovery) and recycling. The remaining volume was diverted to animal feed/compost, incineration (including energy recovery) and recycling. President Chain Store Corporation diverts over 95% of its buried waste. (Note 2)

|

Note(1):The total weight of waste and waste for landfill has been disclosed in the 2023 ESG report. The 2023 ESG report passed SGS verification and obtained AA1000 Type Two High Level assurance.

Note(2): Calculation of the diversion rate of buried waste: total weight of diverted waste/(weight of diverted waste + weight of buried waste) x 100%. The diversion rate of landfill waste at President Chain Store Corporation is greater than 95%.

- Food Loss and Waste Management

President Chain Store Corporation announced the target of halving food waste by 2030 in 2020 (compare with annual volume and reduction ratio of food waste from the stores and factories in base year 2019), President Chain Store Corporation took a detailed inventory to find out where food waste went and started implementing four metrics in 2021, including reducing the amount of scrapped fresh food year by year, reducing production loss at the manufacturers, reducing loss during logistics operations, and increasing the recovery of food waste in the stores. We wll continuously initiate programs to reduce food loss and waste at the source in the three stages of production, order and delivery, as well as retail.

- Upgraded iLove Food Program and Reducing Food Loss and Waste with Technology

As the leader in the retail industry, President Chain Store Corporation is committed to reducing food waste. President Chain Store Corporation launched the iLove Food Map in the app in 2022 for consumers’ easy access to the iLove Food availability in each store, allowing them to take advantage of the convenient program. In 2023, iLove Food prevented the generation of 13,723.31 metric tonnes of food loss and waste with an increase of 3,943.16 metric tonnes from 2022. In addition to working together with consumers to reduce food waste, we extended the shelf life of food in 2023 by taking advantage of new technologies, such as the high-temperature sterilization equipment and special sealing film to reduce food loss and waste from overstock. For more details, please refer to Sustainability Focus–Circular Economy

- Waste Management

The waste produced by President Chain Store Corporation is mainly domestic waste, which belongs to the general waste and general industrial waste categorized by Ministry of Environment with no hazardous industrial waste. The generation of bulk waste is closely related to store operations, including operational waste from upstream fresh food manufacturers, general waste (food waste, general household waste, etc.) generated by store services, and recyclables generated from the stores’ reverse logistics mechanism, etc. Therefore, President Chain Store Corporation takes 2019 as the base year and sets the average waste generated by a single store as the target to reduce 35% in 2023 compared with the base year, and by 45% in 2028 compared to the base year. President Chain Store Corporation follows the 3R principles in the overall waste management strategy to reduce, recycle, reuse, as well as minimizing non-recyclable waste.We mainly focus tackling environmental impact of plastic in our operations. President Chain Store Corporation has engaged in three aspects to reduce plastic, including “reduction at the source,” “innovative packaging” and “encouraging customers to bring their own containers” . We also activly promote store recycling mechanisms in order to reduce reliance on single-use plastics. In addition to controlling the amount of waste generated and ensuring proper disposal, President Chain Store Corporation also effectively combines “convenience” and “recycling” through its many bases to help consumers recycle PET bottles and electronic waste,utilizing waste resource and fulfilling social responsibilities.

- Convenient Recycling Platform

By taking advantage of the multiple bases, President Chain Store Corporation effectively combines “convenience” with “recycling” in helping people recycle electronic waste, including batteries, laptops, optical discs, mobile phones and chargers. To encourage people to recycle through convenience stores, President Chain Store Corporation provides NT$3 to NT$120 of store credit. Moreover, the Intelligent Automatic Recycling Machine that can recycle PET bottles and batteries were incorporated in 2022. The scale was further expanded in 2023 with 140 stores adopting the machine, recycling a total of 7.912 million PET bottles and 2.748 million batteries. The recyclable waste collected is shipped and distributed through the intensive and comprehensive logistics network, then classified and processed after being collected by the reverse logistics system. For more details, please refer to Sustainability Focus –Intelligent Automatic Recycling Machine

- Store Equipment Reuse

In order to provide the most convenient products and services, it relies on a large number and variety of machines. As the wear and tear as well as out-of-service machines cause a great burden on the environment, we have made good use of our flexible dispatch system and a great number of stores to set up the Equipment Refurbishment Center. The recycling system works on existing equipment from renovated and shut down stores, such as air conditioners, refrigerators, oden cooking machines, microwave ovens and so on. It is returned and put to use after inspecting, cleaning and repairing to reduce waste of resources and waste generation, while also saving on equipment procurement costs. In 2023, 34 types of equipment were refurbished and put to use, with the total number of 2616 machines and saving a total amount of equipment procurement costs of NT$93,794,438.

Water Management

Water supply and quality have a direct or indirect impact on the business model of chain stores regarding the products and services we can provide to the consumers. Especially in areas with tight water resources, how to reduce the operational impact on the local water resources is one of the key focus in overall operating value chain.

| Water Efficiency Management Programs |

Management Actions in 2023 |

| Water use assessment to identify opportunities for water efficiency improvements |

President Chain Store Corporation conducts an inventory of water consumption in its operating locations each year to filter water hotspots. In 2023, the total water withdrawal of President Chain Store Corporation was 3,272,705.04 cubic meters, and the total water consumption was 129,723.72 cubic meters. The scope includes stores, head office, shopping centers and district offices. The water use assessment shows that water is mainly used for freshly prepared drinks and cleaning in stores. Water saving and RO equipment have been introduced so far to save water, and resources have been invested to improve water efficiency.

|

| Actions to reduce water consumption |

President Chain Store Corporation has taken the following actions to reduce water consumption:

- Adopt water-saving equipment in operating locations, such as water-saving faucets and toilets.

- Introduce RO water recycling and rainwater collection equipment.

- Establish repairs and timely reporting system for abnormal water leakage in operating locations to reduce waste through leakage. A total of 3,823 water leakage repairs were completed in 2023.

|

| Actions to improve wastewater quality |

Due to the specificities of the industry, the discharge of President Chain Store Corporation is domestic wastewater. Therefore, wastewater discharge management is based on the principle of complying with national water pollution management regulations. Wastewater quality improvement actions include:

- Ensuring that stores are located in areas where the sewage treatment facilities of the building function normally to prevent direct discharge of domestic wastewater.

- If the stores have septic tanks, the tanks will be cleaned regularly to ensure pollution removal efficiency and further reduce the pollution of domestic wastewater to the environment.

|

| Establishment of targets to reduce water use |

President Chain Store commits to reduce the actual water use intensity by 1% in 2021 and 5% in 2025 compared to the base year of 2019.

President Chain Store Corporation manages water usage by focusing on water withdrawal as the management objective. Therefore, the target for water consumption was set to match the previous year's consumption, with a goal of 0.11 million tons for the current year.

|

| Application of water recycling |

For the moment, water-saving taps and toilets have been introduced in all stores. Some stores are also running a pilot program to use RO (reverse osmosis) residual water and collected rainwater for cleaning the stores.

|

| Awareness training provided to employees on water efficiency management programs |

President Chain Store Corporation regularly organizes campaigns that promotes saving water to its employees and stores. It was arranged in the online format in 2023 with a total of 3,840 people watching.

|